Add Value Services

Charng Huah provide one-stop-shop for EMS service. That means we fully integrated manufacturing system from customer product design. Our services include design review for New Product Introduction (NPI), full production and testing, logistics and repairs.

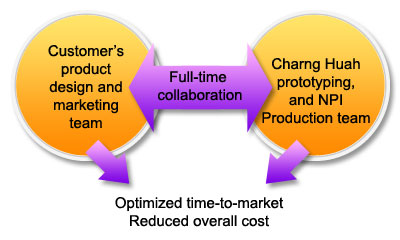

Charng Huah firmly recognizes that startup companies require special support so that they can survive in a time of competition. We offer different customized services to respond with different stages such as Prototyping, NPI and Mass Production and to be a long-tem partner. To minimize overhead cost for mass production and make the fist time to market are our goals.

In order to help our customers develop high quality and low cost designs, we offer high value-added engineering services.

- DFM (Design for manufacturability Analysis)

We provide our customers with production suggestions for designing and how todesign efficiently in MP to save manufacturing cost. - DFT (Design for Testability Analysis)

We provide our customers with suggestions during the design stage such as which test equipment can be used for manufacturing and PCB testability to improve the yield rates. - Concurrent Engineering support service

We work with our customer’s engineers to solve production problems and give feedback on our relative suggestions. - Materials & Logistics

Based on our customer’s different requirements, we provide overall and partial shipment and logistical service.